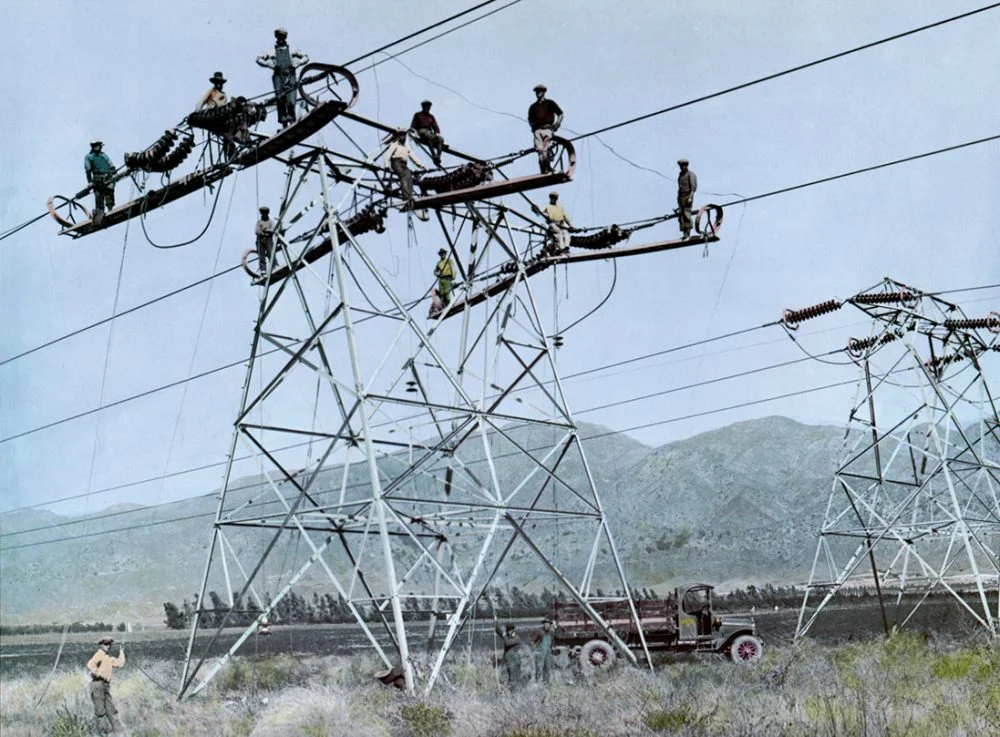

Before safe and effective PPG methods emerged, pioneering lineworkers navigated their worksites with limited grounding knowledge, equipment and procedures.

Personal protective grounding, or PPG, is arguably the most critical safety procedure affecting contemporary lineworkers. Over time, it has evolved to include numerous significant elements that contribute to the success of today’s comprehensive methods and procedures.

To adequately address these elements, this article will be presented in two parts. Part one, which you are now reading, covers PPG’s early years. Part two – scheduled to be published in the October-November issue of Incident Prevention – will cover the critical testing and development that led to the methods and procedures currently in use.

1890-1910: The Beginning

Early power systems were relatively simple. A small generating source was connected to a line that served a small number of customers, or sometimes just one. If a line needed to be worked on, the generator was simply shut down while the lineworkers completed their tasks. There were no other sources of energy or adjacent lines to be concerned with. Some early systems, such as one in Niagara Falls, New York, included parallel lines built from the generating station to the load center. This allowed either line to be de-energized for work while the other line provided service.

As power systems were expanded and interconnected with multiple energy sources, clearing and working on lines and equipment became increasingly hazardous. Disconnects, switches and other devices were developed to isolate equipment and sections of lines. But with no established clearance procedures, accidents began to occur in which lineworkers were electrocuted by inadvertently energized lines. They were also introduced to the hazards of induction from adjacent energized lines. During this period, there was virtually no use of protective grounding.

1910-1930: Initial Mitigation Measures

Lighting streets in larger cities was the first widespread use of electric power in the 1890s. Series circuits supplied several arc lamps. Because streetlight circuits required occasional work, accidents happened when station operators inadvertently closed switches while work was in progress. To improve safety, the industry began to employ switches that could be closed to ground series streetlight circuits after opening them.

Continue reading at Incident Prevention Magazine

For more safety insights for the electric utility industry, check out how to optimize arc flash protection, information about equipment stabilization, or some great information on hand protection from electric shock.

0 Comments