At first blush, the ground sets and jumper sets used in the electrical utility industry appear nearly identical. They are pieces of insulated wire with a clamp on each end, and functionally, they both accomplish related goals as both grounds and jumpers create a temporary detour (much like a traffic detour redirects you around road work) for electricity to flow outside of the regular path. However, the subtle differences in the components of grounds and jumpers ultimately determines their electrical properties and use cases. In short, understanding the difference is critical when selecting the right grounding and jumpering equipment for the job.

Jumpers Keep The Power Flowing

The first lesson kids learn about electricity (after: “don’t stick your finger in that socket”) is that for electricity to flow there needs to be a complete circuit or loop. Our lights come on when we flip a switch because the switch closes the circuit and the electricity can flow (and the lights go out when we trip a breaker because the breaker literally breaks that circuit connection). As with streets and highways, electrical utility systems require regular and emergency maintenance, but just like people still need to be able to drive to their destinations, customers still need electricity to their houses even while work is being done.

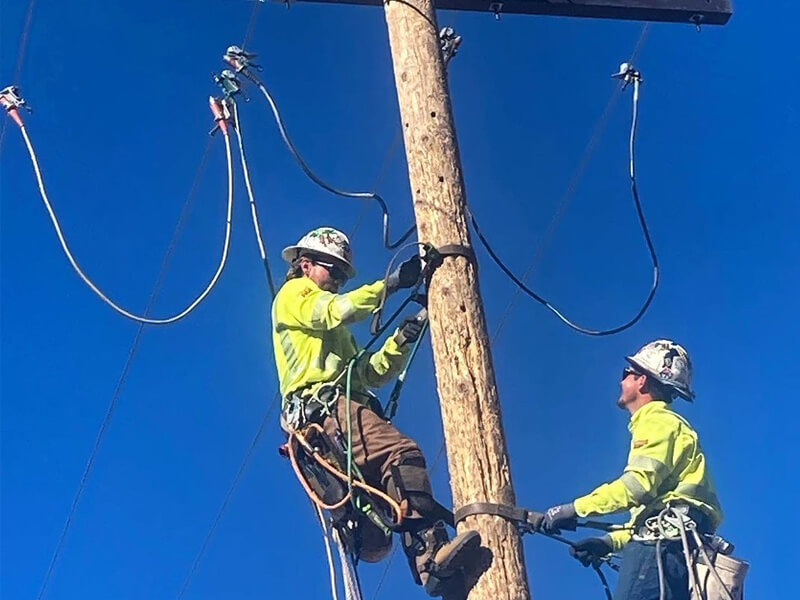

Utility jumper sets provide a temporary electrical path that allows current to bypass a de-energized section of conductor while still keeping the system as a whole energized. In other words, the jumper creates a detour around electrical “road work” in the circuit and gives a path for current to keep moving. Once in place, jumper sets permit linemen to safely perform maintenance or repairs without interrupting service to the remainder of the circuit. In practical terms, jumper sets allow customers’ lights to remain on while utility workers are able to do necessary work on the grid.

Ground Sets Keep Linemen Safe

Ground sets serve a fundamentally different role than jumper sets. Rather than maintaining the flow of electrical current, they are designed to safely divert it. It is similar to a runaway truck ramp, where the safest thing to do to stop a truck that has lost its brakes on a steep hill is to redirect it away from traffic and onto its own ramp. The hope is that the runaway truck ramp will never be needed, but if it is, it can be a life saver. In a similar fashion, ground sets are installed on de-energized conductors or equipment to provide a low-resistance path to ground in the event the system becomes inadvertently energized. It is a safety measure meant to protect utility workers from a runaway truck of electrical current.

Unexpected energization can occur through several mechanisms, including backfeed, induction, or switching errors. Ground sets provide a critical layer of protection by directing fault current away from workers and toward the earth, giving linemen the opportunity to safely clear the line if such an event occurs. Grounds can also be used in creating equipotential zones where voltage differences in the defined area are minimized, thus mitigating the potential for current to flow through the zone. In equipotential zones, even if there is an outside fault causing an increase in system voltage, the increase is uniform within the zone and there will be minimal risk associated with touch or step potential.

Jumper Sets: The Sum of Their Parts

While jumper sets and ground sets share similar basic construction–a length of insulated wire with a clamp on each end–the difference is in the details of the components.

Because jumpers are designed to carry a continuous load of current while in use (or let traffic keep flowing freely), the jumper cable must be insulated and rated based on the voltage (15, 25, and 35 kV) and continuous ampacity (the greater the gauge of the wire, the greater the ampacity). In other words, the traffic detour needs to have sufficient lanes and a high enough speed limit to safely re-direct all the cars on the road or there are going to be problems. The jumper cable needs to be sufficient to not overheat during usage. As with any electrical assembly, a jumper set is only as capable as its lowest-rated component. When configuring jumper sets, it is essential to ensure that the cable, clamps, and ferrules are appropriately rated for the anticipated load, or else you might be trying to divert a four lane highway down a gravel country road.

Tallman Equipment jumper set configurations are available in 15, 25, and 35 kV ratings, with conductor sizes ranging from #2 through 4/0. Larger conductor sizes provide greater ampacity. It’s like having more lanes on the highway to allow more traffic to move through. Although jumper clamps and ferrules are typically rated for 400 amps, the conductor size often becomes the limiting factor. For example, #2 jumper cable is rated at 200 amps, 1/0 at 250 amps, 2/0 at 300 amps, and 4/0 at 400 amps. A jumper set using #2 cable and 400-amp clamps will therefore still be limited to a 200-amp rating. That said, smaller conductor sizes are lighter and more flexible, which can improve ease of handling and installation in the field.

The size and style of clamps for the jumper set is the next major consideration. Clamps are often either chosen based on an ACSR size (such as 477 ACSR) or a conductor diameter range (e.g. 0.162″-2.0″). Different styles of clamps can be used on jumper sets (e.g clear, c-type, and duckbill). Each utility or contractor may have its own standard requirements (always check with your utility to ensure you are following their standards).

Ground Sets: The Sum of Their Parts

Ground sets offer a little more variety than jumper sets, depending on the application. Standard ground sets are the most similar to jumper sets (two clamps, ferrules, copper wire…etc.), but there are also specialty ground set options for different jobs. The variations in those ground sets typically comes down to the kind of clamps or other forms of attachment that make the set suitable for situations such as substation grounding or tower grounding or equipment grounding.

Unlike jumper sets, ground sets are not designed to carry continuous current. Instead, their purpose is to safely conduct fault current to ground during abnormal conditions. Or to continue the traffic analogy, the runaway truck ramp is meant as a one time exit for that runaway truck. It does not need to be a four lane highway. It just needs to be sufficient for the biggest truck that might come rumbling toward it. As a result, grounding cable is generally not rated for high voltage insulation (most grounding cable is rated to 600 V). Grounding wire has minimal insulation that is more concerned with protecting the inner stranding from damage from outside elements so that when it is needed, it is still in working order.

Ground clamps are where most of the variation lies. C-type clamps can be serrated or un-serrated and are often used on stranded conductor. Flat-face clamps clamp onto flat surfaces like tower legs. All-angle clamps, as the name indicates, offer a variety of approach angles to the conductor to give greater flexibility in setup. Clamps are connected to the conductor via a ferrule. Ferrules are compressed onto the conductor threading for a secure connection without creating too much resistance. The ferrules then connect securely to the clamp to ensure an unimpeded flow of current.

Grounds and Jumpers at Tallman Equipment

Tallman Equipment are your source for the most reliable ground and jumper sets in the utility industry. Sets are built to order with components selected from the most respected brands in the business and a proprietary process that ensures a secure and robust clamp assembly. Sets can often be built the same day to whatever length is required. All assemblies are tested to ensure they are free of defect and serialized for simplified tracking.

Tallman Equipment also specializes in cleaning and refurbishing used grounds and jumpers. The Tallman team fully disassembles, cleans, and tests each component of the jumper and ground assemblies to ensure they are still operating as well as they did when first put into service. Our customers often remark that they cannot believe they are receiving their own equipment back because it truly is in “like new” condition.

Trust Tallman

Tallman Equipment has been serving linemen and the utility industry for over 70 years. We take pride in doing the right thing for our customers, and that includes providing linemen with the best tools and equipment, including ground sets and jumpers, to get the job done. We are committed to being a one stop shop for linemen, where we will always provide quality, convenience, and reliability.

0 Comments