In a world full of acronyms and initialisms like OSHA, ASTM, IEEE, and ANSI, it’s easy to get confused about what they all mean and when they matter. Take ASTM for example. At Tallman Equipment, we say we are an ASTM member, and we build our temporary protective ground sets to ASTM standards. But do you know why that’s important?

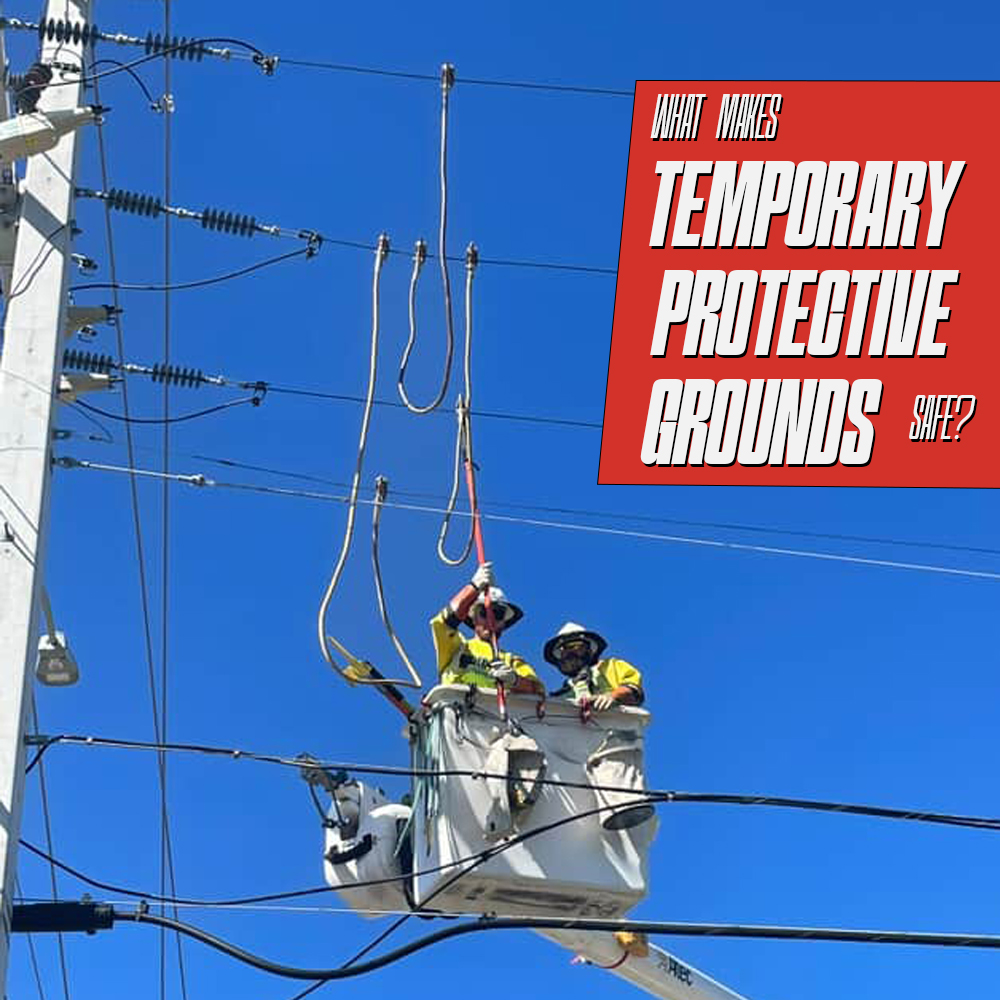

Linemen depend on temporary ground sets every day as a layer of protection against unexpected fault hazards, and we build them to ASTM standards so we know we are giving the best to our customers. Here’s what being built to ASTM standards means and why it matters to you.

What Is ASTM?

ASTM International writes standards for manufacturing and industry. In 1902, railroads were growing fast, and the steel being used was not always the same quality. It was resulting in rails failing. Scientists and engineers saw that without clear standards, railroads would remain unsafe. ASTM was created to fix that problem.

Initially called the American Society for Testing Material (later known as the American Society for Testing and Materials and now just as ASTM International), the organization grew over time as other industries saw the same need. Today, ASTM standards are used in thousands of industries for materials, products, and services.

Each standard is written by committees formed from industry experts. These groups include members both from producers and users of the product. No single company is allowed to be the majority on any committee to prevent monopolization and self-dealing.

ASTM standards for manufacturing are much like recipes in the kitchen. They tell manufacturers how something should be made, tested, or used so the result is consistent every time.

-

A recipe lists ingredients, measurements, and steps so the dish turns out the same no matter who cooks it.

-

An ASTM standard lists materials, dimensions, test methods, and performance requirements so a product works the same no matter who makes it.

If someone skips steps or changes ingredients in a recipe, the food might not turn out right, and if a manufacturer ignores parts of the standard, the product may not perform safely or reliably.

ASTM is not a government agency, so following its standards is usually voluntary. However, government rules and agencies (such as OSHA), safety laws, and contracts often use ASTM standards as their requirements.

What Is OSHA?

OSHA stands for the Occupational Safety and Health Administration. It is part of the U.S. Department of Labor. OSHA’s job is to keep workers safe both by establishing safety rules and by investigating safety incidents.

In the electrical utility industry, OSHA sets rules to protect linemen. For temporary protective grounds, the relevant regulation is known as OSHA 29 CFR 1910.269.

OSHA’s only specific rule for ground sets in 29 CFR 1910.269 is that they must handle at least as much current as a #2 AWG copper cable, however 29 CFR 1910.269(n) does recognize ASTM F855 as the industry standard. So, while OSHA does not require temporary protective ground sets to officially be built to ASTM F855, if your ground sets meet ASTM F855, they easily meet OSHA’s requirements.

ASTM F855: The Industry Standard

ASTM F855 Standard Specifications for Temporary Protective Grounds to Be Used on De-Energized Electric Power Lines and Equipment is the main standard for temporary protective grounds used on de-energized power lines and equipment. The latest version is ASTM F855-25 (the last two digits indicate the year the standard was adopted), and it is a perfect example of why ASTM came to exist in the first place. The detailed rules for making temporary protective grounds remind us that, like cooking, there are many ways to mess up a recipe. Changing the materials, how it’s made, or how it’s tested can lead to something that doesn’t work right and could be unsafe.

Unlike OSHA, ASTM F855 gives detailed specifications for temporary protective grounds. It covers appropriate ground clamps, ferrules, cable, and how the whole ground set is assembled and tested. The standard includes charts to show how each part must perform during electrical faults. By following ASTM F855, manufacturers are sure to produce a safe and reliable product.

Ground Clamps

In basic terms, ASTM requires ground clamps to stay closed, connected, and conductive. They cannot break, melt, or come loose. The standard also explains different clamp styles, jaw types, and grades to help choose the right clamp for the job.

Will you be installing your temporary protective grounds by hand or with hot sticks? Onto what kind of cable are you clamping? How much potential voltage could there be? The ASTM standard addresses which types of clamps are appropriate depending on the answer to each of those questions.

Ferrules

Ferrules can easily become an afterthought, but they are critical to building a robust ground set assembly. ASTM F855 makes sure ferrules are strong both mechanically and electrically. They must fit the cable and clamp correctly and create a solid, low-resistance connection.

The standard explains proper materials and crimping methods. It does not require a specific crimp tool or die. Instead, it requires a result: a tight crimp with no loose strands or gaps. Put simply, ferrules cannot be the weak point in the ground set.

Grounding Cable

ASTM F855 also covers grounding cable. The cable must handle fault current without melting, breaking, or pulling apart. The standard includes rules for copper stranding and construction so the cable stays flexible, strong, and reliable through repeated use.

Complete Ground Set Assembly

ASTM F855 looks at the entire ground set assembly as one system, not just the parts. The goal is to make sure all components work together as a coherent unit. Per F855, new temporary protective grounds must be electrically tested for sufficient conductivity before a final physical check for signs of damage due to the electrical test. Any damage could mean the assembly would not provide sufficient protection when in use in the field.

ASTM F855 does not cover in-service testing. This is covered by ASTM F2249.

What ASTM F855 Does Not Cover

The purpose of ASTM F855 is not to give instructions on how to install temporary protective grounds (the industry standard comes from IEEE, the Institute of Electrical and Electronics Engineers). ASTM is also not present on the jobsite to ensure utilities and linemen are using appropriately rated, assembled, and tested ground sets.

What ASTM F855 does do is make sure that ground sets built to the standard are strong, reliable, and safe when they are properly rated and installed. It is still up to utilities, contractors, and linemen to follow OSHA rules and safe work practices.

Why Linemen Trust Tallman

Tallman Equipment is a proud ASTM member. With more than 70 years of experience in the utility industry, we understand what linemen need to get the job done. Our tool experts are ready to help answer questions and provide top-level service.

From ground sets, jumper sets, tool sales, tool repair, rubber goods testing, or tool rental, we are a one stop shop for all your electrical utility work needs.

0 Comments